Metatronic Calculations

Melissa Lockwood has developed a technique that turns fashion industries mass production pattern waste fabrics into additional garments during the garment design phase.

The fashion industry is currently ranked among the top polluting industries. 92 million tons of fabric go into landfills annually. A portion of this is thrown away during factory production.

The technique Melissa invented enables designers to design with the intent of keeping fabric out of the landfills. The concept works within a set of parameters and can enable fashion designers to utilize fabrics they would normally not consider usable.

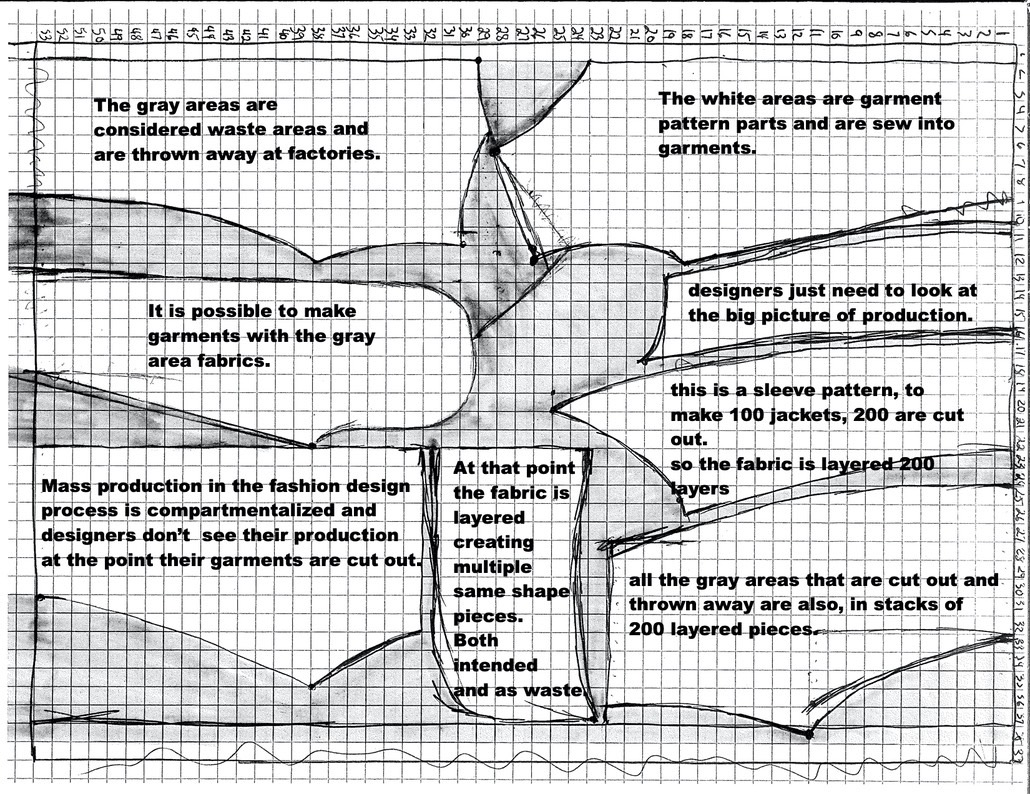

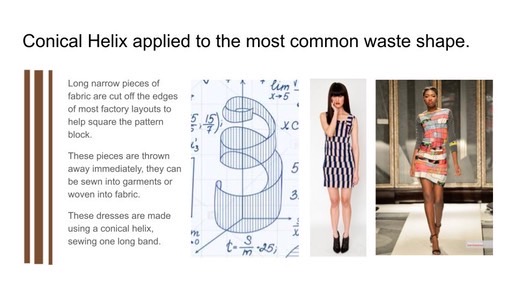

In mass production of clothing a lot of fabric is thrown away and goes to the landfills. This happens when the garments are cut out, the fabrics between the garment pieces are thrown away.

During the pattern cut out procedure large amounts of fabric are laid out in stacks on tables, then patterns for garment parts are placed on the fabric and cut out and saved to be sewn into garments. The odd shapes found that are created in multiple between the intended pieces are not used.

The waste areas are created because of the non uniformity of the shapes of the pattern pieces. The edges of the garment parts are varied, making it necessary to leave the spaces. All the fabric that is between the pattern pieces is usually thrown away. This is typically 10-30% of the fabric. Melissa’s system takes into account these odd between shapes and uses them to create clothing.

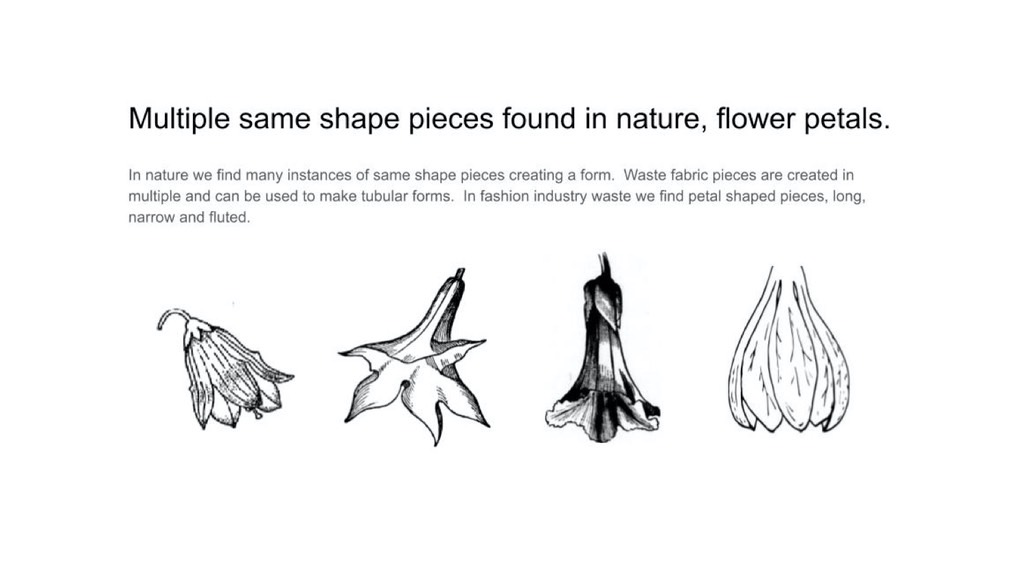

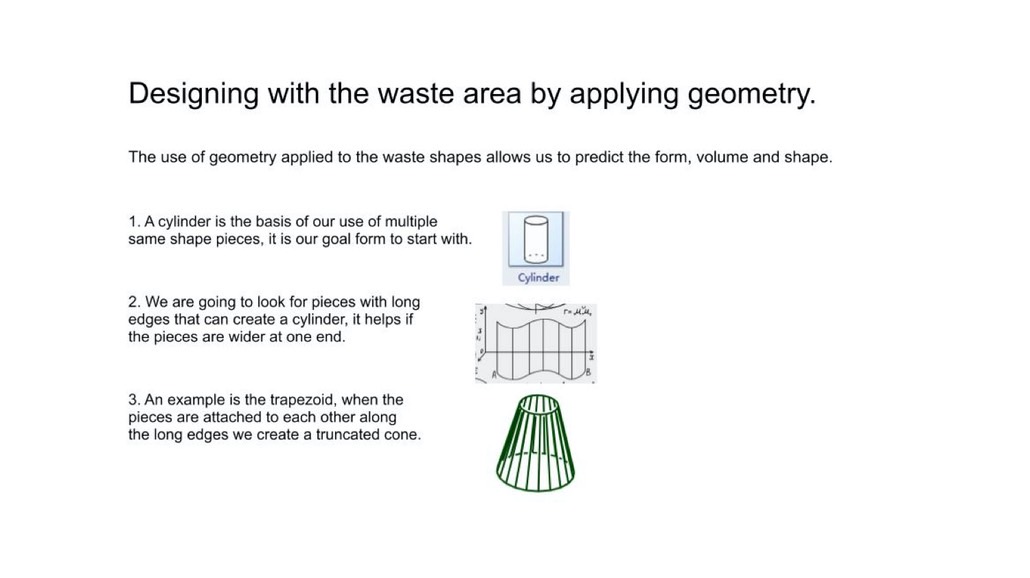

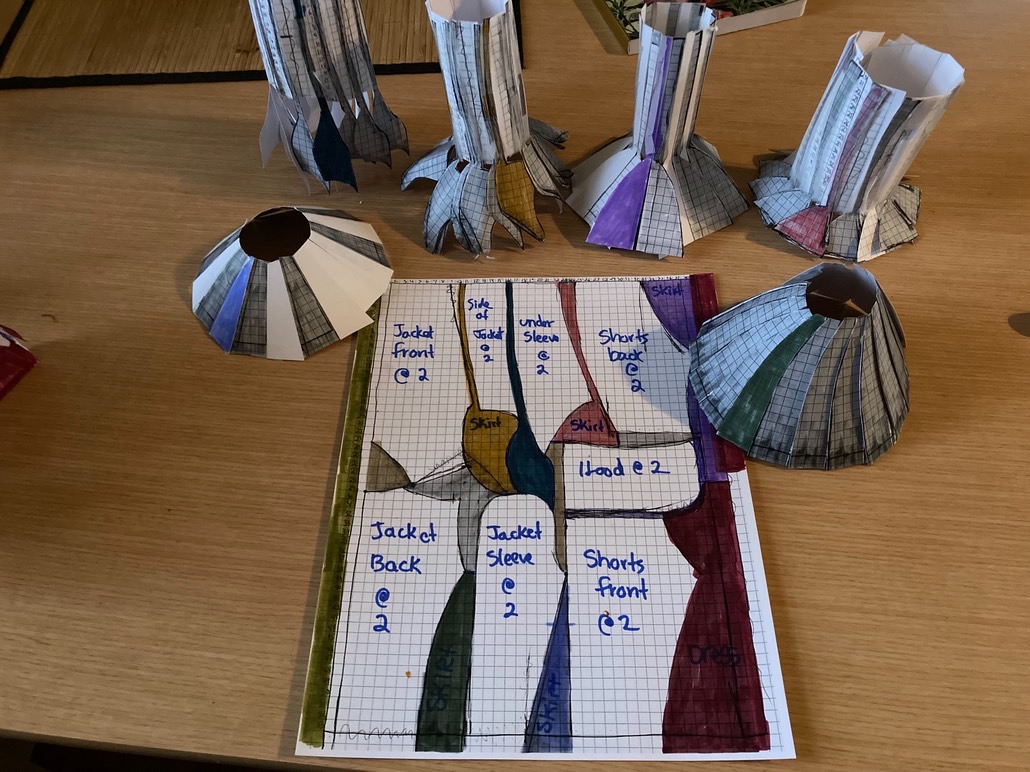

Being a design scientist, 3D thinker and natural engineer she created cylinders with the multiple same shape pieces found in garment layout waste. She uses a common technique of assembling forms with multiple same shape pieces. What her system does differently is, it uses radial projection to create cylindrical shapes that include the biomorphic aspects.

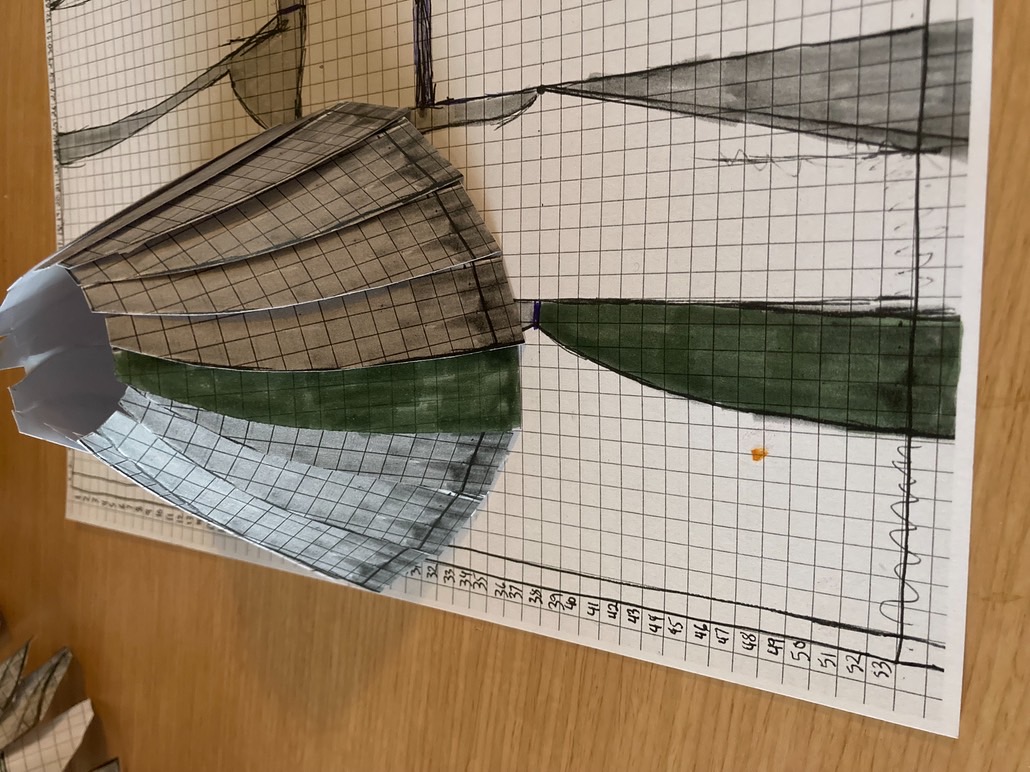

With the remnant area shapes one orients the pieces to form as close as possible to a cylinder. Since the human form is basically a cylinder, creating cylinders with whatever shape is presented, one can create a garment. The wearable structures emerge with the application of radial projection.

In the process of laying out pattern parts for cutout one is presented with finite shapes and a finite number of these shapes. With this information it is possible to predetermine the uses of these shapes. When designers determine the quantity of garments they will make and the layout of said garments they can then begin designing subsequent garments based on the use of the multiple same shape pieces found in the in-between shapes.

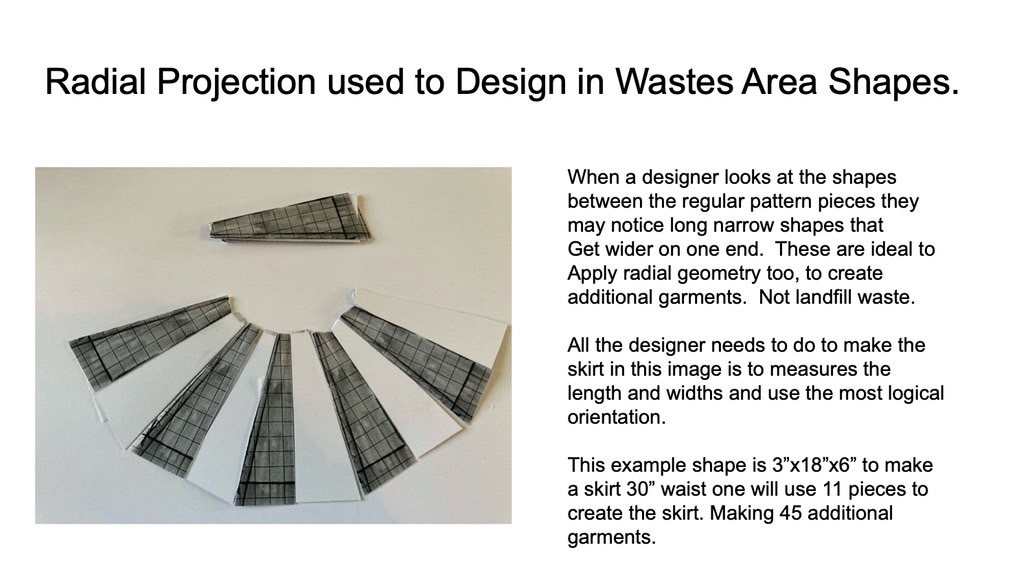

The assembly of a garment comes down to the width and length of the found pieces. Due to the general consistency of shapes created when common items like pants, shirts and skirts are laid out it is really common that long narrow pieces which widen at one end occur. These are easy to make clothing with.

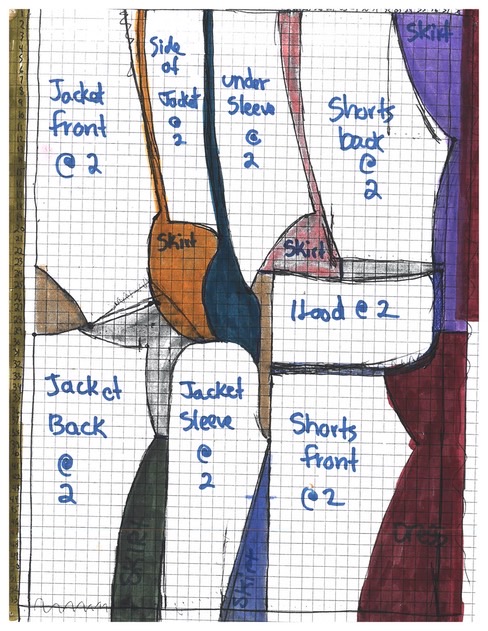

This is a pattern layout, the colorful pieces are usually thrown away. In mass production the regular pattern pieces and the waste area shapes are made in stacks 50 plus pieces. The technique I am working with allows us to design garments with the stack of fabric in the pattern layout waste area.

Usually designers create garments with pattern pieces spread across fabric on the horizontal plane. My technique observes the block waste pattern areas from the horizontal and includes the stacks of same shape pieces created in the vertical.

When designing a pattern that includes the waste pieces it is helpful to think of how the waste pieces are created in quantity. When you view the layered fabric in factory situation with the pattern block in place, you can view the pattern in 3D on the vertical axis, utilizing the stacks of same shape pieces that are created during multiple same shape garment production.

With the cylinder form in mind, I recognized the potential of use of many common waste shapes. A basic dress can be compared to a cylindar. I chose long narrow shapes that widen at one end. The selection of shapes is interesting, I noticed a lot of repeat waste area shapes, in different factories. With the creation of shirts, blouses and jackets the the sleeve pattern create a shape found repatedly. This shape is a long narrow piece fluted at one end.

These are 3D forms made fron the shapes between the standard pattern pieces.

With the wastes pattern shapes created in same shape multiple pieces it is possible to make multifaceted garments with them. Applieing radial geomertry to the multiple same shape pieces with the cylinder in mind I was able to create multifaceted garments without altering the found shapes.

A skirt made with a waste shape from the pattern block, 1 skirt per 10 jackets is created.

This technique gives designers another tool to utilize production waste fabrics in the fashion industry and lower landfill waste. Less waste can be achieved by changing the block pattern waste fabric area into a design space.

This is different from traditional zero waste pattern making, It uses the pattern layout area on the vertical and horizontal. It can make non zero waste patterns zero waste. It is possible to make traditional garments and have zero waste with this method.

With the use of radial projection the same shape pieces can be preplanned during garment design and incorporated into the patterning block. This technique transforms waste fabrics into additional garments. Using radial geometry I realized that many of the pieces thrown away are usable to make garments.

Combining the helix into the radial cylindar

Consultation/Training

Melissa Lockwood is available in person and online for consultations.

Melissa’s main impetus is to lower the impact of fashion industry waste on our planet. She recognizes the potential of this practice to greatly reduce fabric waste. She offers her experience, technique and to teach designers how to create garments with the fabrics they usually throw away.

Melissa is available for online consultations, in person studio visits and factory visits. Her goal is to empower designers with a tested theory and technique so the industry will become regenerative and sustainable in a major way.

Melissa recently finished two nine month Design Science Studio incubator sessions with the Buckminster Fuller Institute ’s Design Science Studio and habRitual. There she was able to focus on the mathematical details and how to teach it to designers.

The method she teaches is a really easy and clear process when applied to garment pattern blocking with the pattern layout waste areas. While a designer lays out the patterns, Melissa can teach how to recognize garments in the overall 3D perception of the fabric in its totality.

If you would like to learn more about this project, process and or schedule a learning session feel free to contact Melissa at:

melissa@iqtest-nyc.com

Thank you, Melissa